Cooling Markets

Huge opportunity in a range of markets

MicroPower’s current focus is primarily on the power generation properties of our technology, but cooling applications remain a long-term target.

Our limited testing in Peltier mode indicates that the superior efficiencies seen and validated by accredited third parties in our technology in Seebeck mode would also translate to a superior coefficient of performance (C.O.P.), also known as the Peltier Coefficient, than most commonly available thermoelectric devices.

The key advantage that our technology offers remains the same in both modes – being able to operate in high temperatures – which enables our technology to be a viable contender in most industrial applications.

Cooling deep well drilling is a good example where there is a need to protect expensive electronics from high heat, typically in the range of 400°C and above. MicroPower’s product roadmap includes plans to enter the cooling markets in the years to come, though possible strategic partnerships may accelerate these plans.

Refrigerators & Beverage Coolers

In recent years, standard thermoelectric cooling has been making inroads into the refrigeration market. Thermoelectric devices act as heat pumps and, with much smaller size and much lighter weight compared to typical compressors, make it possible to build refrigeration units that are far more efficient, virtually silent and vibration-free.

While residential and commercial refrigeration are viable target markets, the true advantage is more evident in the highly specialized niche market for refrigerators and freezers in medical and laboratory applications such as drug and vaccine storage. From portable units to large walk-in units, MicroPower technology will be able to offer highly competitive performance efficiencies.

Electronic Devices

Thermoelectric coolers can be miniaturized to help alleviate the heat problems associated with high density packaging. Under these conditions, material performance is important as well as interfacial materials with higher thermal conductivity. Some electronic equipment intended for military use is cooled using thermoelectric devices, due to their reliability and low weight.

Thermoelectric coolers are a common component in thermal cyclers, used for the synthesis of DNA, in photon detectors in astronomical telescopes, spectrometers, and upscale digital cameras to eliminate pixel noise which can cause speckled images. In all cases, greater cooling efficiency will enable longer operational time, or less weight.

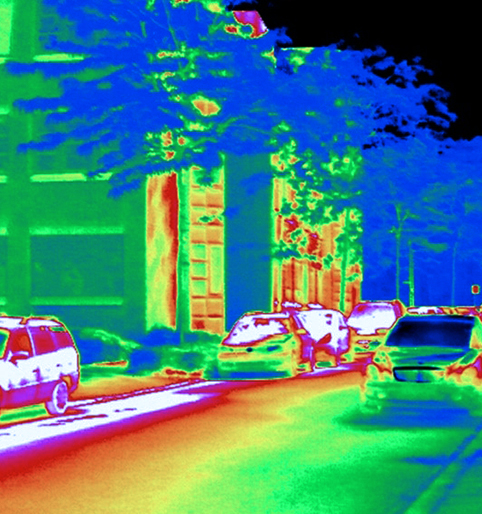

Infrared Imaging

Infrared imaging products are intended for military, law enforcement, homeland and industrial security applications, and in locations such as nuclear plants, oil refineries and pipelines, water treatment plants, port authorities and penitentiary facilities. Products provide video images using the infrared portion of the spectrum to allow viewing in darkness or through fog or smoke.

Image resolution quality improves if the focal plane arrays of the cameras are cooled to temperatures as low as liquid nitrogen temperature, which is approximately 77K (-321°F or -196°C). For handheld or portable operation, the cooling technology must be lightweight, small and energy efficient. MicroPower cooling devices, once developed, would be well placed to serve this need.

Silicon Chips

Advances in semiconductor technology, including shrinking feature size, increased transistor density, and faster circuit speeds, have led to overheating becoming one of the biggest issues for silicon chip manufacturers and companies integrating these chips into phones, laptops, etc. Indeed, microscale hot spots can significantly degrade performance and reliability.

The application of conventional thermal packaging technology to provide uniform chip cooling results in lower allowable chip power dissipation or overcooling of large areas of the chip. Consequently, the IT industry has shown considerable interest in making use of thermoelectric cooling devices that could selectively cool down the localized microscale hot spot.

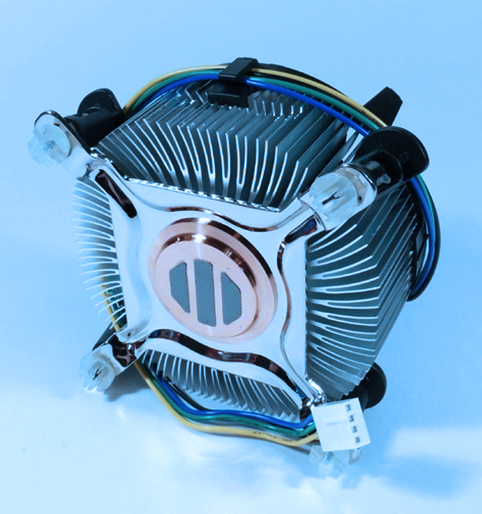

Computer Cooling

The heat created in a PC or laptop must be dissipated in order to keep the various components within their safe operating temperatures. Currently, this is done using heat sinks to increase the surface area dissipating the heat, or fans, which speed up the exchange of air heated by computer parts for cooler ambient air.

The replacement of a computer cooling fan is very desirable in the mind of this industry due to reliability and power issues with the motor. A solid-state cooler fixed to the primary heat sources would be well received. MicroPower Modules could cool only the few main sources of heat on a computer printed wiring board. This could reduce the heat transfer problems so that convection and radiant cooling would suffice thereby eliminating the fan.

Seat Cooling

The use of thermoelectrics in vehicle seats to cool occupants is already a feature in upscale automobiles, with seat cushions designed to transfer heat away from the occupier’s body while cooling to the required temperature. Seat cooling technology also allows drivers to use their air conditioning system less frequently, thereby reducing gas usage, and the need for gases such as Freon.

These substances are believed to be extremely damaging to the atmosphere, and are considered to have hundreds of times the Global Warming Potential (GWP) of Carbon Dioxide. The spread of this technology through the automotive industry has been restricted largely due to cost, but we believe our technology could widen seat cooling to the mainstream.

Solid State Headlamp Cooling

The auto industry has been actively introducing high-intensity LEDs to replace incandescent and halogen head lamps since 2004. Their use reduces the weight of the lamp system and reduces energy consumption. However, LEDs actually produce a significant amount of heat per unit of light output which poses thermal management challenges for plastic headlamp housings.

In addition, this heat build-up materially reduces the light output of the emitters themselves. Keeping LED junction temperatures low at high power levels requires additional thermal management measures such as heat sinks and exhaust fans which can be quite expensive. A highly efficient MicroPower cooling device, as an active element of the lamp, could provide a desirable alternative.