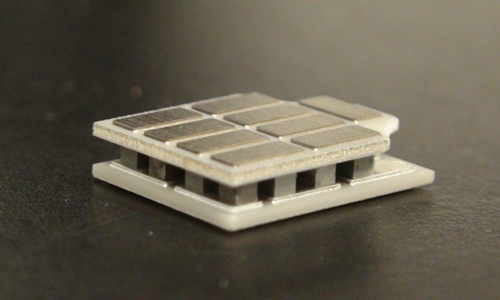

(March 10th 2016) – Hamilton, Bermuda – MicroPower’s technology has received a strong boost this week, with the results of third party testing of the company’s modules confirming that they significantly outperform other thermoelectric products in the marketplace.

One of the first outside parties to receive MicroPower’s prototype modules was the US Army Research Laboratory (ARL), which is a recognised authority on thermoelectrics. ARL began their independent characterization and testing of the modules in January 2016, and the results are extremely encouraging.

While it is noted that further testing will be required to establish the exact efficiency, the results show that MicroPower’s modules are “best in class in terms of normalized Watt/kg level”.

Determining exact efficiency is indeed a widespread issue in the thermoelectric industry, with different metrics, testing methods and standards often making apples vs apples comparisons impossible, not to mention the fact that customers become disenchanted with the whole industry when competitors’ modules do not perform as stated in their data sheets.

MicroPower believes that by working with recognized bodies such as ARL, and the US National Renewable Energy Laboratory (NREL), the company can play a role in helping to develop standards that will allow those both inside and outside the thermoelectric community access to credible information about the efficiency and power generating capabilities of different devices.

Another third party with experience in testing and evaluating thermoelectric modules is Power Practical, who has been searching far and wide to find more efficient thermoelectric modules to use in their innovative Power Pots. The product uses a thermoelectric device in the base of a pot to generate electricity using the temperature difference between the heat of a flame, and the cooler liquid in the pot.

Power Practical has been testing MicroPower’s modules since the second half of 2015, including tests with the US military, and has reported “a significant performance improvement over current TEGs”. The companies continue to work towards further collaboration in 2016.

“We have long believed that our modules are substantially more efficient than any other commercial modules available today, so it is reassuring to hear the same from both government and industry customers who have been testing everything available for the benefit of their own business,” said Max Lewinsohn, MicroPower’s Chairman. “Today, our modules are efficient enough to allow entry into several markets, and we expect to increase power and performance levels even further in future iterations of our devices,” he added.